Carbon Ceramic Brake Refurbishing vs. Replacement: Why Gen 3 Technology Is the Smarter Choice

- Triton Motorsports

- Nov 6, 2025

- 7 min read

The rise of carbon ceramic brake refurbishing services has created a lot of buzz in the high-performance community. On paper, it sounds like a great idea: send your worn carbon ceramic rotors to a company, have the friction layer re-coated, and get them back “like new.” But as with most things that sound too good to be true, the process comes with serious trade-offs — both technical and financial.

At Triton Motorsports, we’ve spent years developing Gen 3 Carbon Ceramic Brake (CCB-H) technology — the same design used in our systems for McLaren, Lamborghini, Porsche, Ferrari, Audi RS, and Corvette Z06 platforms. Through that development, we’ve learned that refurbishing worn CCM discs is not only less efficient but can actually compromise the core structure of the rotor itself.

This article explains why refurbishing old carbon ceramic rotors isn’t the performance bargain it seems, and why replacing them with next-generation Gen 3 carbon ceramics is the smarter, safer, and ultimately more economical solution.

Understanding How Carbon Ceramic Brakes Work

Before exploring the refurbishing process, it’s important to understand how carbon ceramic discs are made and what makes them special.

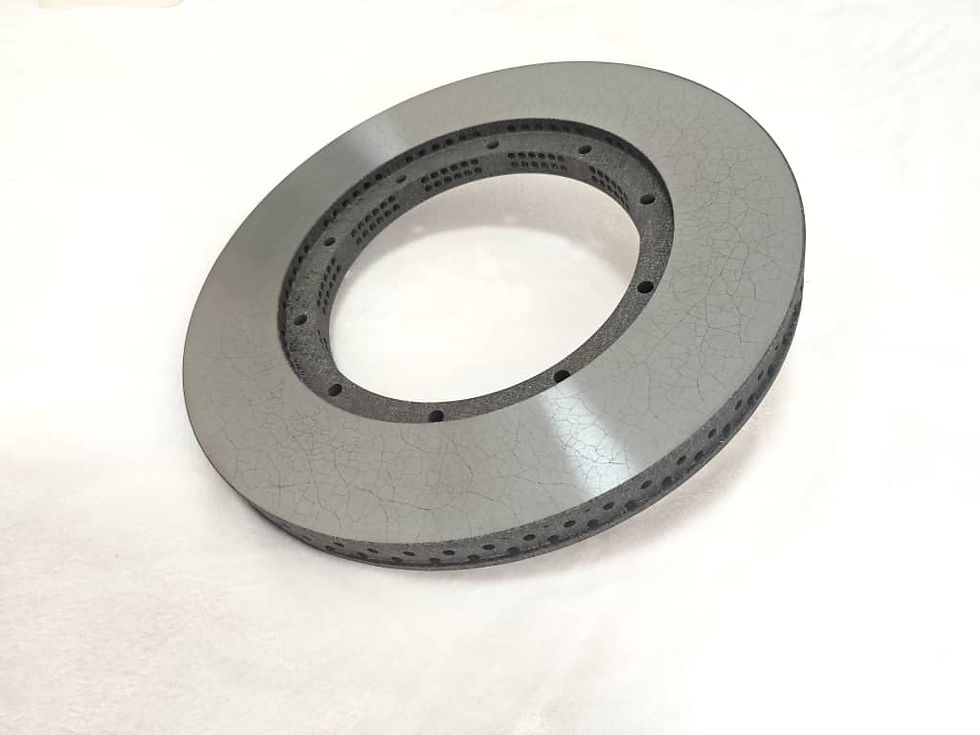

Most OEM “carbon ceramics” — such as those fitted to Lamborghinis, Ferraris, and McLarens — are CCM (Carbon Ceramic Matrix) rotors. These are made by blending short, chopped carbon fibers with a resin binder, then heating the mix to carbonize it. The carbon matrix is then infiltrated with silicon carbide (SiC), which creates a hard, wear-resistant friction surface.

The key advantage of carbon ceramics lies in their:

Ultra-lightweight structure (up to 60 % lighter than iron).

Extreme heat tolerance (up to 1,000 °C).

Fade-free performance even under sustained track use.

Resistance to corrosion and oxidation.

However, their manufacturing process is complex and costly — and once the carbon matrix is damaged or worn, repairing it properly is nearly impossible without rebuilding the rotor from the ground up.

What Refurbishing Actually Does

“Refurbishing” or “re-coating” services typically involve grinding off the old friction layer and re-applying a new silicon carbide (SiC) surface through a high-temperature furnace bonding process.

At first glance, this seems like a reasonable way to restore a rotor’s surface finish. But here’s the catch: that process requires re-exposing the rotor to the same extreme heat (1,400–1,600 °C) used in initial manufacturing. And those temperatures can have unintended — and irreversible — consequences for the rotor’s core.

When a used CCM disc is reheated to such high temperatures:

Core mass loss occurs. The existing carbon matrix loses material integrity as portions of the carbon fibers burn off.

Structural density decreases. The rotor becomes more porous and less able to manage thermal stress.

Fiber continuity is destroyed. Chopped fibers weaken further, introducing micro-cracks and delamination zones.

Dimensional instability increases. Re-baking alters the rotor’s shape and molecular balance, sometimes requiring re-machining.

The result may look new on the surface — but underneath, the rotor has lost structural strength and thermal capacity.

The Hidden Cost of Refurbishing

Most refurbishing companies quote anywhere from $2,000–$2,500 per disc. On the surface, that sounds appealing compared to OEM replacements that can cost $20,000+ per set.

But what often goes unnoticed are the hidden expenses and drawbacks:

1. Downtime

Your car must be taken apart, the rotors shipped for inspection, processed, re-coated, and shipped back — often taking 4 – 6 weeks or more. During this time, your car is completely undriveable.

2. Risk of Core Damage

If the refurbishing process overheats or underbakes, the internal carbon structure can degrade beyond recovery — meaning you’ve spent thousands for rotors that may crack prematurely.

3. Old Technology Remains

You’re still left with a first-generation CCM rotor, even after refurbishment. None of the material or bonding upgrades from newer-generation carbon ceramics are added — just a new surface layer.

4. Similar Total Cost

A brand-new Triton CCB-H replacement rotor often costs about the same per rotor once shipping, downtime, and refurb fees are considered. You’re simply paying to re-use outdated technology.

CCM vs CCB-H: What Has Changed

The difference between first-generation CCM rotors and Triton’s third-generation CCB-H discs is not minor — it’s fundamental.

Property | Factory CCM | Triton CCB-H |

Carbon Fiber Type | Short, chopped | Continuous long-strand |

Fiber Orientation | 2D random | 3D woven matrix |

SiC Application | Surface infiltration | Deep homogeneous infusion |

Core Density | Moderate | High-density structural core |

Heat Tolerance | ~700 °C | 1,000 °C + |

Fade Resistance | Moderate | Exceptional |

Lifespan | 40–60 k mi | 100 k mi + |

Serviceability | Non-rebuildable | Re-hat / hardware serviceable |

Triton’s CCB-H rotors use continuous carbon fibers woven in a 3D matrix before SiC bonding. This structure is significantly denser and far more thermally stable than the chopped-fiber structure of traditional CCM rotors.

Even if you refurbish a CCM disc, you cannot achieve this level of molecular reinforcement — because the fiber continuity simply isn’t there.

The Science of Core Mass Loss

When a used CCM disc is re-baked, its carbon core undergoes mass depletion — essentially losing part of its internal carbon lattice as volatile elements oxidize under high heat.

This loss means:

Reduced heat conduction capability.

Lower mechanical stiffness under heavy braking.

Increased susceptibility to thermal cracks.

In extreme cases, the rotor’s inner structure becomes brittle, meaning that even though the friction surface looks “new,” the disc has actually lost the ability to perform under repeated high-load conditions — the exact scenario for which it was designed.

Thermal Stability and Fade Resistance

A properly engineered carbon ceramic disc must maintain structural uniformity across thousands of heat cycles. Once the core integrity is compromised through re-baking, that stability is lost.

Drivers who have refurbished rotors often notice:

Diminished braking consistency.

Reduced cold-bite performance.

Faster onset of fade during track sessions.

By contrast, Triton CCB-H discs maintain consistent performance across an enormous temperature range — giving drivers repeatable pedal feel lap after lap.

Time = Money: The Downtime Factor

If you’re sending your discs away for refurbishment, your car will be off the road for a month or more. Even assuming the job is successful, you’ve spent significant time and money with no performance gain.

By comparison, Triton replacement discs are available ready to ship, and installation takes only a few hours. That means no waiting, no guesswork, and no risk of shipping damage or incomplete refurb results.

A Smarter Investment: Replace, Don’t Re-Bake

When you compare the two options side-by-side, it becomes clear that buying new Gen 3 carbon ceramics is not only safer but also more cost-effective long-term.

Factor | Refurbished CCM | Triton CCB-H Replacement |

Cost per Disc | $2,000–$2,500 | $2,500–$2,800 |

Downtime | 4–6 weeks | 2–3 days |

Core Strength | Reduced | Full factory integrity |

Heat Rating | Moderate | Extreme (1,000 °C +) |

Longevity | 1–2 years typical | 5–10 years |

Technology | Gen 1 CCM | Gen 3 CCB-H |

Warranty | Limited / none | Full warranty coverage |

Weight, Performance, and Handling

Both OEM and refurbished CCM discs retain roughly the same weight. Triton’s CCB-H rotors, however, are optimized for even lighter unsprung mass without sacrificing strength.

Each disc is 1–2 lbs lighter than an equivalent CCM, improving:

Suspension responsiveness.

Cornering grip.

Overall lap-time consistency.

Weight reduction below the suspension line pays huge dividends in real-world handling — benefits that refurbishing can’t offer.

Material Evolution: The Role of Continuous Fiber Weaving

The shift from chopped to continuous carbon fiber reinforcement marks one of the biggest leaps in carbon-ceramic technology. Continuous fibers allow load paths to remain uninterrupted, distributing stress evenly throughout the disc.

Older CCM discs use short, random fibers, which fracture easily under heat cycles. Once broken, they can’t re-bond — meaning every reheat cycle during refurbishment makes them weaker.

Triton’s 3D continuous weave prevents this problem entirely, ensuring maximum stiffness and fatigue resistance even after years of hard driving.

Pad Compatibility and Surface Performance

Another often-overlooked issue with refurbished rotors is surface hardness inconsistency. The re-applied SiC layer may not bond uniformly, creating hard and soft zones that accelerate pad wear and vibration.

Our CCB-H discs, on the other hand, undergo multi-stage surface curing to achieve perfect friction balance and pad compatibility. They’re tested for:

Uniform surface hardness (±2 HRC).

Perfect roundness and flatness tolerance.

Predictable bedding-in characteristics.

They pair flawlessly with both OEM carbon ceramic pads and Triton’s proprietary pad compounds, ensuring silent, smooth, fade-free operation.

Long-Term Reliability

Refurbished discs often look new at first but deteriorate quickly due to weakened core integrity. Cracks and delamination can appear within months of aggressive driving.

By contrast, Triton CCB-H rotors are rated for 100,000 + miles of street use or multiple seasons of track use with minimal wear. The higher density and uniform SiC saturation mean the discs remain stable even under continuous high-energy braking.

The Hidden Liability of Refurbished Brakes

Aside from the technical shortcomings, refurbished rotors pose another risk — liability. Most refurbishers explicitly state that their product is “for off-road use only” and offer no structural warranty.

If a failure occurs, the financial and safety consequences fall on the owner. By contrast, Triton carbon ceramic rotors are supplied with full warranty coverage and tested to the same standards as OEM equipment.

Why Gen 3 Carbon Ceramics Are the Future

With CCB-H, Triton has achieved what refurbishing can’t:

True long-fiber continuity.

Uniform SiC bonding through the entire depth.

Precision billet aluminum hats with full floating systems.

Superior heat tolerance and structural stiffness.

It’s not just an upgrade — it’s an evolution of the material science behind performance braking.

Conclusion – The Educated Choice

Refurbishing may seem like a shortcut to save money on carbon ceramic brakes, but when you factor in the risks — downtime, cost, and compromised performance — it’s clear that buying modern Gen 3 replacements is the smarter decision.

With Triton CCB-H carbon ceramic rotors, you’re not just restoring performance — you’re stepping into a new era of braking technology. Lighter, stronger, cooler, and engineered for endurance, they deliver the confidence your supercar deserves.

Whether your car wears a Lamborghini, McLaren, Audi RS, or Ferrari badge, Triton’s replacement discs offer unmatched stopping power and peace of mind.

Comments